17th January, 2024

What Is PPE In Health And Safety?

PPE stands for Personal Protective Equipment. In health and safety, you wear PPE to keep yourself safe. It protects the wearer from health and safety hazards and is a last line of defence. Examples of PPE include hard hats, safety footwear, hi-viz clothing, ear defenders, safety goggles, and gloves.

PPE is used in most workplaces to keep people safe. In this blog post, we will look at the different types of PPE, what it's used for, and its limitations and benefits.

What does PPE stand for?

PPE stands for Personal Protective Equipment. It is the equipment used by an individual to keep themselves safe.

PPE is a personal protective measure, which means that it usually protects an individual rather than a group.

Examples of PPE include hard hats, safety footwear, hi-viz clothing, ear defenders, safety goggles, and gloves.

PPE examples:

- Safety helmets

- Hard hats

- Bumper caps

- Safety glasses

- Safety goggles

- Face shields

- Face screens

- Visors

- Earplugs

- Ear defenders

- Gloves

- Gauntlets

- Sleeving

- Aprons

- Hairnets

- Overalls

- Chemical suits

- Safety boots

- Foundry boots

- Chainsaw boots

- Dust masks

- Respirators (RPE)

- Hi-viz clothing

- Harnesses

- Life jackets

Why do we use PPE?

We use PPE in health and safety to protect people when there is a risk of harm. It's a last line of defence for the wearer. If a hazard gets through the other controls, PPE is the last thing they have to keep them safe.

As you can see from the examples above, there are many types of PPE. Different types of PPE are used to protect from different hazards in different ways.

Some items of PPE protect your head, like a hard hat to protect you from projectiles, or a hairnet to stop your hair from getting tangled in the equipment you're using.

Some PPE is worn to make you more visible, like high-visibility clothing worn on railway work, in factories and on construction sites.

PPE can protect you from health hazards and/or safety hazards. For example, a dust mask protects you from inhaling harmful fibres (health hazard). A hard hat protects you from a brick falling on your head (safety hazard).

You don't just have to pick one item of PPE - you can use several. As long as they are compatible with each other, and work well together.

For example, on construction sites, hard hats, safety boots and hi-viz vests are often the minimum items of PPE required to enter the site. So the person can be seen and has some basic protection from general construction site hazards.

Types of PPE

- Head protection

- Hearing protection

- Respiratory protection (RPE)

- Hand and skin protection

- Eye protection

- Foot protection

- Fall protection

- Protective clothing

- Visibility clothing

When should PPE be worn?

Health and safety measures are an important part of any work activity. And PPE is part of that.

Employers have legal health and safety responsibilities when it comes to protecting people at work. Employees also have legal health and safety responsibilities for using the control measures provided.

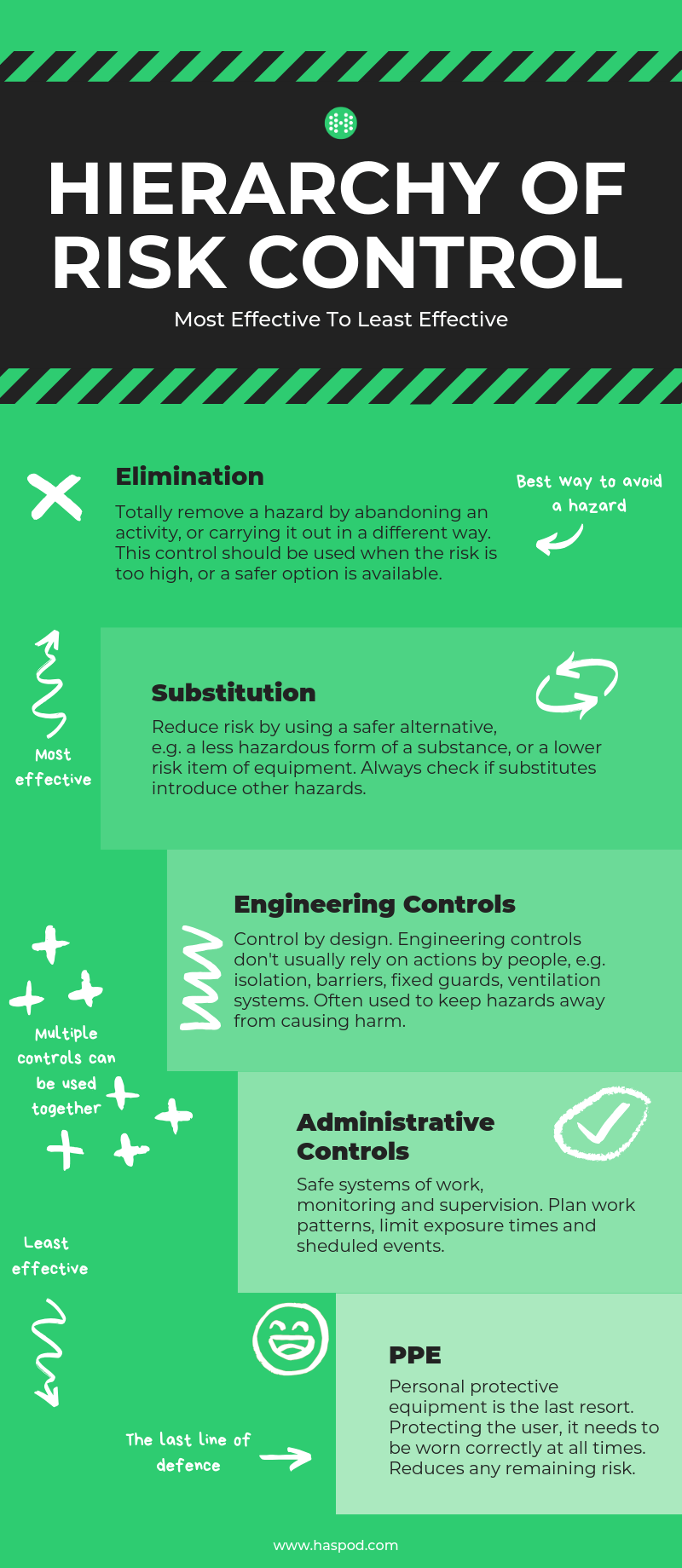

PPE is one of the options available to consider when you are looking at putting in place safety measures for a task or activity. But, when you check the hierarchy of risk control, you'll notice that PPE is not the most effective control measure.

In fact, PPE is the last resort for protecting people.

PPE should never be the first option because it only protects one user at a time. It also usually relies on user activation. The person needs to remember to wear PPE and wear it properly. And you need to rely on them not to take it off during the task or activity.

For example, a hard hat may protect you from cuts and a cracked skull if a brick falls on your head. But it doesn't stop the impact. So does the hard hat really give you full protection?

And what if it falls on the person next to you who just took their hard hat off to scratch their head?

Other controls can make this situation much safer. Toeboards and netting can stop the brick from falling in the first place, protecting both the workers underneath. Your hard hat should be there as an extra precaution, not as the only control measure.

PPE is an important control measure, but it should be used to control risks that have already been reduced by other controls, or if no other controls are suitable.

Some circumstances where PPE is needed include:

- Maintenance work

- During emergencies

- Where alternative controls are not possible or practical

- When a risk assessment shows that some risk remains after other controls implemented

PPE limitations

- PPE only protects the person wearing it and not others

- PPE must be used properly to work properly

- PPE needs to be worn all the time to provide protection

- PPE must be replaced when it stops providing protection (damaged, contaminated or expired)

While some of the above points are true for other control measures, the maintenance and monitoring requirements with PPE can be much greater compared with one single collective control measure.

For example, a ventilation system can protect 50 people and is one piece of equipment to test and inspect. 50 people each wearing respiratory protection is 50 items of equipment to monitor, check and inspect.

When you are thinking about using PPE to control a hazard, you should first consider the other ways you can reduce the risk.

For example, ear defenders could reduce the noise at the ear. But it doesn't eliminate the hazard, the work area is still noisy, and other people may be affected. An enclosure around the equipment generating the noise could reduce the noise at its source, creating a safer environment for everyone.

And a dust mask or respiratory protective equipment (RPE) is only suitable if it forms a seal so that contaminated air cannot bypass the filter.

PPE benefits

While PPE shouldn't be your first consideration, it will still be an important part of your safety management. If other controls fail, PPE can still protect the user as a last line of defence.

PPE might not be the first control measure, but since risk can never be zero, you'll often need PPE in addition to the other controls you put in place.

PPE is often quick and easy to implement. And users know they are wearing it and you can see them wearing it, so it's easy to know when they are protected.

- PPE can be used if other controls are not practical

- PPE can be used in temporary work situations while other controls are implemented

- PPE gives immediate protection

- PPE might be the only practical control measure in emergencies

Need more benefits? Here are 50 reasons you should wear and use PPE.

PPE considerations

Like any control measure, PPE must be used correctly for it to work properly.

Here are some considerations for PPE use in your business:

- The equipment is suitable for the wearer

- The equipment is suitable for the task

- The user is trained in its correct use

- When multiple items are used, PPE is compatible with each other

- PPE is maintained

- PPE is replaced when damaged or expired

- PPE is suitably stored

- PPE use is supervised and enforced

PPE can be a simple and straightforward control measure, but it isn't one size fits all.

Consider your worker's different shapes and sizes. Often, PPE can be adjusted or supplied in a different size to fit the wearer. Wearing the wrong fit can give the illusion of safety, without the benefits of actually being safe.

Now you should know what PPE is, and when to use it to create a safer work environment. Here are 50 reasons you should wear and use PPE, and you can download the free PPE toolbox talk to raise awareness on site.

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Better health and safety...

We are here to help you and your business put safety in everything.

Learn MoreRecent posts like this...

50 Reasons Why You Should Wear And Use PPE

If you have ever struggled to get your team to wear and use their PPE correctly, or you are not sure why you need to wear PPE yourself, here are 50 reasons why you should wear and use PPE. After reading these 50 reasons, why wouldn't you wear PPE?

Read Post

15 Quick Ways To Reduce The Risk Of Slips, Trips And Falls

Slips, trips and falls are huge contributors to the number of workplace injuries each year. The great news is that you can reduce slips, trips and falls relatively quickly, and all of the suggestions in this post can be put in place on a budget. Here are 15 quick and cheap ways to reduce the risk.

Read Post

Is Health And Safety Training A Legal Requirement?

For all business types, health and safety training will be a legal requirement in one form or another. Your team might need external training courses, qualifications, and certificates. Staff may need in-house inductions, on-the-job training, and toolbox talks. Often, a mixture of both is required.

Read Post