9th March, 2023

The Hierarchy Of Risk Control

How should you reduce risk? One of the best ways to assess existing controls and identify new control measures is to consider how effective they are - based on the hierarchy of risk control. In this blog post, we will look at the full list of controls, and how to apply them to your work activities.

Hazards are present in all work environments. Controlling the risks that these hazards present is part of creating a safe work environment. But how would you know how best to control a hazard?

There are so many control measures available - should you wear a mask, damp it down, extract or enclose it?

Pick the wrong control and you could be at more risk than you need to be - more than is safe. Not all control measures are equal.

Enter, the hierarchy of risk control.

What is the hierarchy of risk control?

You will probably already have some safety measures in place for a task or activity. Controlling risks means assessing the adequacy of existing controls or introducing new controls to prevent harm.

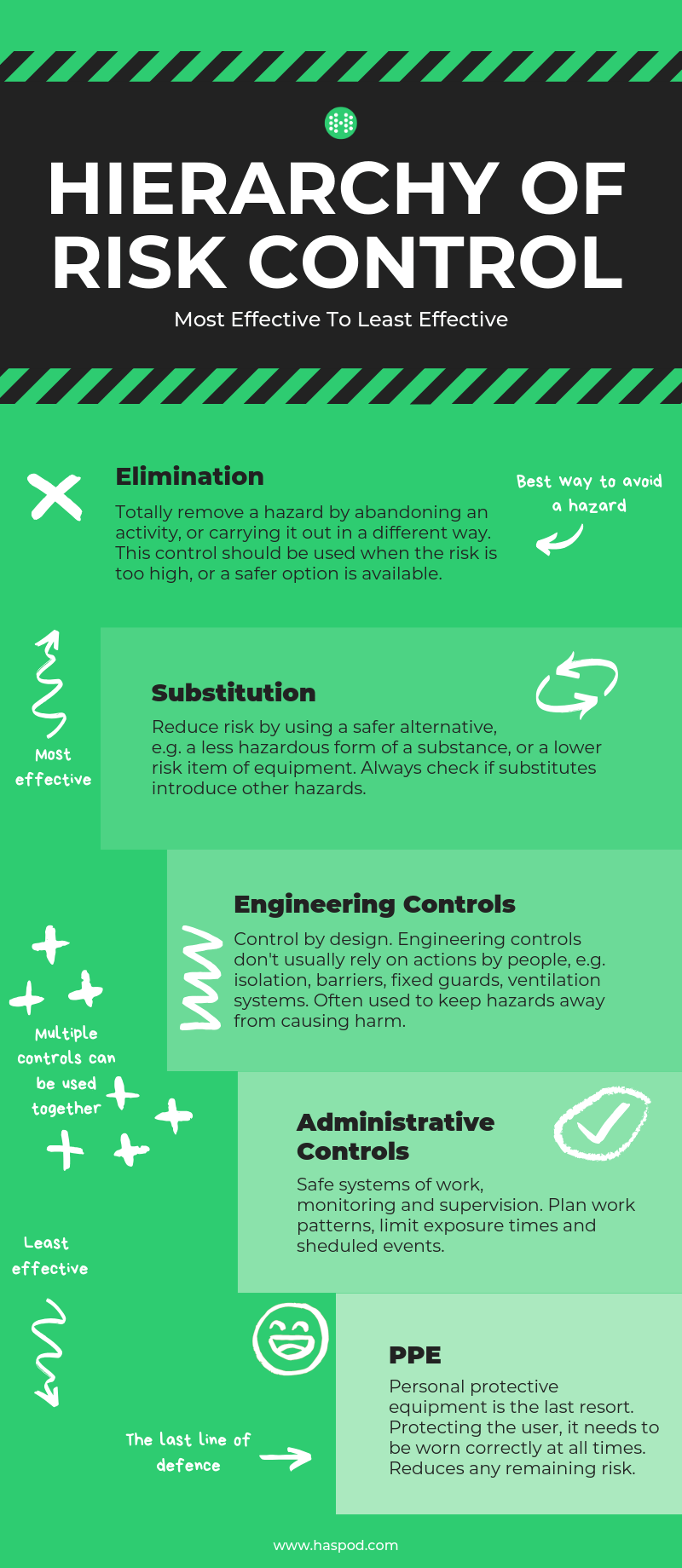

When controlling risks, there is a hierarchy of risk control which should be followed:

- Elimination

- Substitution

- Engineering controls

- Reduced or limited exposure

- Good housekeeping

- Safe systems of work

- Training and information

- Personal protective equipment (PPE)

- Welfare

- Monitoring and supervision

- Reviews

This is often simplified into a 5 tier system:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- PPE

The top control 'elimination' is the most effective, and the list follows in order from most effective to least effective.

When do you need the hierarchy of risk control?

As the name suggests, the hierarchy of risk control applies to control measures. These are the things you put in place to control risk. You can use the hierarchy of risk control when you assess existing controls, or when you are introducing new controls.

In practice, this will usually happen during risk assessment.

Step 3 of the HSE's 5 steps to risk assessment involves evaluating if existing control measures are adequate, or if more should be done to reduce risk. One of the best ways to both assess existing controls and identify new control measures is to consider how effective they are based on the hierarchy of risk control.

The hierarchy of risk control is used when undertaking risk assessment activities, to control hazards and minimise risk. Once you have calculated the level of risk, you should decide on the precautions or controls needed to reduce the risk.

To control risk, you need to do everything 'reasonably practicable'. This means balancing the level of risk against the measures needed to control the real risk in terms of money, time or trouble. Always aim to reduce the risk as low as is reasonably practicable, also known as ALARP.

Can you eliminate the risk by getting rid of the hazard completely? If the hazard cannot be eliminated, then how can the risks be controlled so that harm is unlikely?

The hierarchy of risk control is usually considered alongside the principles of prevention for reducing risk.

Let's take a look at each of the 5 key areas of the hierarchy of risk control, from most effective, to least effective.

Elimination

Elimination is the best and most effective control. If a hazard is serious, and the risk cannot be reduced to an acceptable level, then it should be eliminated.

You might be able to eliminate a hazard by doing the job differently. Maybe you could use alternative methods or equipment? For example, work at height can be eliminated if the work can be safely carried out using extendable poles.

Substitution

You might not be able to fully eliminate a hazard and its risks. Maybe risk can never be zero. But could you swap a hazard for something less risky instead?

With changes in technology and advances in manufacturing, safer alternatives are always becoming available, so you should always consider substitution when reviewing your control measures.

For example, new equipment might have lower noise and vibration levels, reducing health risks. Or a scaffold could be used for safer access instead of ladders. Or a different substance might be less dangerous, for example, a safer cleaning solution.

Engineering Controls

Engineering controls are a good way of controlling hazards at source. Examples include:

- Enclosures

- Barriers

- Guards

- Insulation

- Extraction

- Fixed ventilation

Engineering controls include anything designed and built to make the work environment safer. This type of control usually provides a safer environment for everyone, rather than an individual.

For example, an enclosure separates a hazard from everyone outside it. And extracting hazardous fumes or gases at the source means cleaner and safer air for everyone.

Administrative Controls

Sometimes, it's not possible to reduce the risk any further by changing the equipment or substance. But you can still reduce the time people are exposed, through work patterns, monitoring and supervision.

Examples of administrative controls include:

- Reduced or limited exposure

- Good housekeeping

- Safe systems of work

- Training and information

- Monitoring

Safe systems of work like permits to work can be used for high-risk activities, like hot work or work at height.

Training and inductions can be carried out to raise awareness of how to carry out a task safely or the hazards that are involved.

And regular, scheduled activities can be used to maintain safety - like inspections, testing, good housekeeping and cleaning.

PPE

PPE is the last line of defence you have. It's the last barrier between a person and the hazard. It might be the least effective control on the list, but it doesn't mean it's not important.

Where risk remains, PPE can be a good way of protecting individuals. It can give protection if the correct PPE is selected for the hazard, and is used and maintained correctly.

And just because PPE is last on the list, doesn't mean you should only use it when you can't use the other controls. You can (and should) use multiple controls.

Multiple Controls

Don't make the mistake of thinking you can only pick one type of control. For complete protection and to reduce risk to a safe level, multiple controls are often required.

Control measures can work well together.

For example, in a paint spraying activity, you might substitute an oil-based paint for water-based paint (substitution). But you might still choose to carry out the work in an enclosure with fixed ventilation (engineering controls). You could also put in place work patterns to reduce time exposure to hazardous substances and a cleaning schedule (administrative controls). And provide workers with gloves, overalls and goggles to prevent skin and eye contact (PPE).

A combination of two or more controls from the hierarchy is often needed to adequately control the risk, particularly high risks, to a level that is 'reasonably practicable'. Remember, risks should be as low as is reasonably practicable before work goes ahead.

Even if you have substituted a high hazard for a low one, you still have a legal responsibility to reduce risk. And, just because PPE is last on the list, doesn't mean it can't be a good way to control risk, especially when used with other control measures. Sometimes, PPE can be vital to the safety of users, especially in emergencies or difficult work environments.

In addition to the hierarchy of controls, the Management of Health and Safety at Work Regulations contain the principles of prevention, which gives a legal outline for implementing preventative measures.

Find out more about risk assessment and the five steps to risk assessment with our online introduction to risk assessment elearning training course.

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Better health and safety...

We are here to help you and your business put safety in everything.

Learn MoreRecent posts like this...

Is Health And Safety Training A Legal Requirement?

For all business types, health and safety training will be a legal requirement in one form or another. Your team might need external training courses, qualifications, and certificates. Staff may need in-house inductions, on-the-job training, and toolbox talks. Often, a mixture of both is required.

Read Post

HSE Fee For Intervention Charges Explained

FFI stands for 'fee for intervention', which was introduced under the Health and Safety (Fees) Regulations 2012. FFI aims to recover the HSE's costs, including inspection, investigation and enforcement action, charging businesses that are in breach of health and safety regulations.

Read Post

How To Plan For Better Health And Safety At Work

If you want better health and safety, you need to plan for it. And who doesn't want to stay safer and have fewer accidents and ill health in their workplace? In this blog post, we look at how to plan for better health and safety at work.

Read Post