16th March, 2022

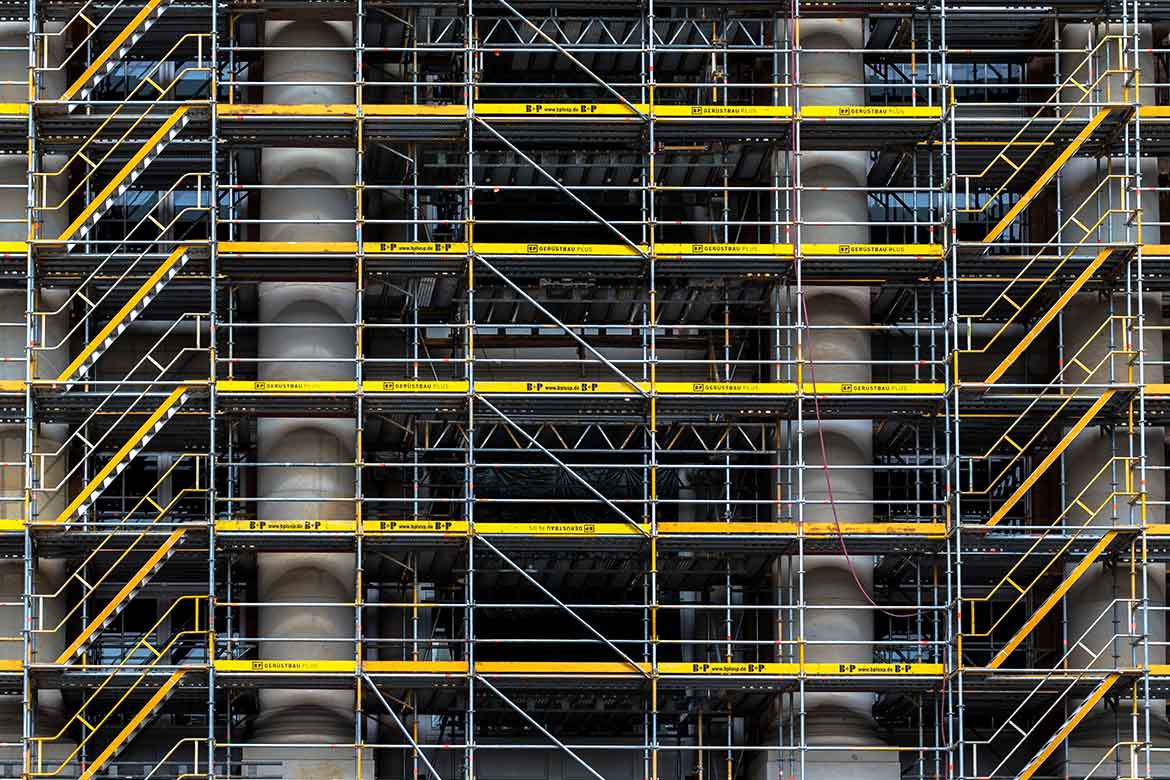

40+ Daily Scaffolding Safety Checks And Common Faults

There are many different elements to a scaffold to check and maintain for safety. In this blog post, we will look at a checklist of over 40 scaffolding faults you should look out for. And we discuss why (and when) you need to check scaffolds and their components to keep them safe and secure.

Sometimes work at height can't be avoided. And scaffolds are often used as a safe form of access.

But work at height is dangerous. It's our top construction safety hazard. And over 60% of deaths from work at height involve falls from scaffolds, ladders, working platforms and roofs. This statistic shows that while scaffolding aims to provide a safe working platform for work at height, it isn't always the case.

Scaffolds are complex temporary structures. And one that will often need to be altered during its use so work can take place at different levels. Because as a building is constructed, or if refurbishment and maintenance works are carried out, different areas may need to be accessed at different times.

If scaffolding isn't designed correctly, installed safely, or maintained appropriately, it can become unsafe.

But how do you know if your scaffold is safe?

In this blog post, we detail 40 common scaffolding faults. If you find even one of these, it could undermine the whole structure.

There are so many different elements to a scaffold. Scaffolding safety checks should be made on all of the different components, including:

- Footings

- Standards

- Ledgers

- Bracing

- Putlogs

- Transoms

- Couplings

- Bridles

- Ties

- Boarding

- Guardrails

- Toeboards

- Ladders

All scaffold design, erection and installations must be carried out by a competent person. Once the scaffold is signed off and handed over for use, you need to make sure it stays safe, and suitable for the work.

A competent person must carry out a scaffold inspection at least every 7 days noting any defects and corrective actions taken.

You can keep a record of scaffold inspections to ensure you comply with legal requirements with the scaffold register form.

There are many ways a scaffold can become unsafe during its use. It could get damaged, from contact with a vehicle or site plant, or bad weather like strong winds. It could be altered by someone who is not authorised to do so. Or it could be overloaded.

The importance of ensuring scaffolds remain safe is seen all too often when the worse happens, a scaffolding collapse occurs.

Regular scaffold inspections are a legal requirement. Find out more about the 3 times when a scaffold must be inspected.

A scaffold collapse usually results in serious injuries or fatalities. It could harm those working on the scaffold. And also injure anyone beneath or near the scaffold when it collapses.

For the safety of those using the scaffold as a means of access and working platform, it is important to be able to recognise common scaffolding faults and stop use should any unauthorised alterations be made, e.g. removing guardrails or moving boards. Unauthorised alterations increase the risk of falls and make the scaffold an unsafe place of work.

Here is a checklist of common scaffolding faults, that need urgent attention if identified:

Footings

The footings of the scaffold are usually the metal base plates at the bottom of the scaffold standards, on top of timber sole plates/boards to distribute the load over the ground.

Faults:

- Soft and uneven

- No base plates

- No sole plates

- Undermined

Standards

Standards are upright tubes or poles used as vertical support.

Faults:

- Not plumb

- Jointed at the same height

- Wrong spacing

- Damaged

Ledgers

A ledger is a horizontal tube tying standards horizontally.

Faults:

- Not level

- Joints in the same bay

- Loose

- Damaged

Bracing

Bracing tubes span diagonally to strengthen and prevent movement.

Faults:

- Some missing

- Loose

- Wrong fittings

Putlogs and transoms

A putlog is a tube flattened at the end spanning from a ledger to the wall of a building. A transom is a tube spanning across ledgers to tie a scaffold transversely and may support a working platform.

Faults:

- Wrongly spaced

- Loose

- Wrongly supported

Couplings

Scaffold couplings are metal components or fittings used to connect the scaffold components together.

Faults:

- Wrong fitting

- Loose

- Damaged

- No check couplers

Bridles

A bridle is a tube fixed across an opening or parallel to the face of a building to support the inner end of a transom or tie tube.

Faults:

- Wrong spacing

- Wrong couplings

- No check couplers

Ties

Ties are used to connect the scaffold into stable parts of a building or structure to keep the scaffold stable.

Faults:

- Some missing

- Loose

- Not enough

Boarding

Scaffold boards are usually timber and butted together to provide a safe horizontal working platform.

Faults:

- Bad boards

- Trap boards

- Incomplete

- Insufficient supports

Guardrails & toeboards

Guardrails are horizontal tubes fitted to standards along working platforms to prevent falls, and toeboards are usually timber and fitted at the base of working platforms to prevent persons, materials and tools from falling.

Faults:

- Wrong height

- Loose

- Some missing

- Damaged

Ladders

Ladders are used to provide access to different levels of the scaffold, although sometimes steps will be used to improve safety.

Faults: - Damaged - Warped - Insufficient length - Not tied - No handhold available

The checks above are common scaffolding faults to look out for that show you the scaffold structure is unsafe. If you find any faults during a visual check, you should get a competent person to inspect and rectify the issues, before using the scaffolding.

Any scaffolds installed on your sites should have the following arrangements in place:

- Handover certificate

- 7-day inspections

- Daily visual checks

- Alterations by a competent person

- Stay within safe working loads

7-day inspections are the maximum periods between inspections, but remember that if anything changes that may affect the structure of the scaffolding, for example, bad weather or damage, you will need to inspect the scaffold sooner.

Scaffolds are designed to provide a safe working platform and access for working at height. As with any temporary structure, check your scaffolding regularly to make sure it remains safe throughout its use.

Remember to get your scaffold inspected by a competent person at 7-day intervals, and after installation or changes to the scaffold structure.

Use the scaffold inspection checklist to keep a record of your scaffold checks on site.

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Need health and safety documents?

Search hundreds of health and safety documents ready to edit and download for your construction projects.

Find DocumentsRecent posts like this...

The 10 Rungs (And Rules) Of Ladder Safety

Used right, ladders are not particularly dangerous. But ladders are involved in over a quarter of all falls from height, causing serious and sometimes fatal injuries. Our 10 rules of ladder safety will help you use ladders correctly, to help prevent you from getting hurt.

Read Post

Securing Your Construction Site For Christmas Shutdown

Christmas is often the longest period your construction site will be closed, so site security is especially important. Because when you're away, things can go wrong. Shutting down your site and securing it from trespassers can help make sure that you don't get any nasty surprises.

Read Post

10 Winter Safety Tips For Construction Workers

Working outside in the winter can be a challenge for keeping warm, but winter work can also create safety hazards and increase the risk of accidents on site, due to poor weather conditions, reduced lighting, and hidden dangers. Here are 10 winter safety tips for construction workers.

Read Post