15th October, 2025

Top 5 Construction Safety Hazards (And How You Can Control The Risks)

If you work in construction, these are the safety hazards most likely to harm you. Updated with the latest accident statistics from the HSE, we look at which safety hazards are most likely to kill or injure you in construction and how you can control the risks on site.

Perhaps this blog post should be called "The worst 5 construction safety hazards". After all, I don't have a top construction safety hazard any more than I would have a favourite illness. Nonetheless, here are our top 5 construction safety hazards.

By top 5, we mean, if you work in construction, these are the safety hazards most likely to harm you*.

1. Work at Height

Construction work is dangerous. There were 51 construction workers killed in 2023/24 according to HSE statistics. And over 50% of construction deaths were from falls from height!

That means that working at height is the most dangerous job on a construction site.

Falls from height also accounted for 20% of non-fatal injuries in construction, compared to 8% across all industries.

So what's behind this statistic?

Well, the high number of falls within the construction industry is largely because your exposure is increased. Work at height in some form can be found on nearly every construction site. So, if you work in construction, you are more likely to work at height. And when falls from height do occur, the resulting injuries are typically serious, and often fatal.

Major work at height, on roofs and buildings under construction, can be extremely hazardous if not carefully planned. Roofs and floors under construction, fragile roof materials such as roof lights or damaged roof sheets, add the risk of falls through the roof structure, along with the obvious risk of falls from the roof edge.

Read more about controlling the risks of falls in our recent blog post getting safety right when working at height.

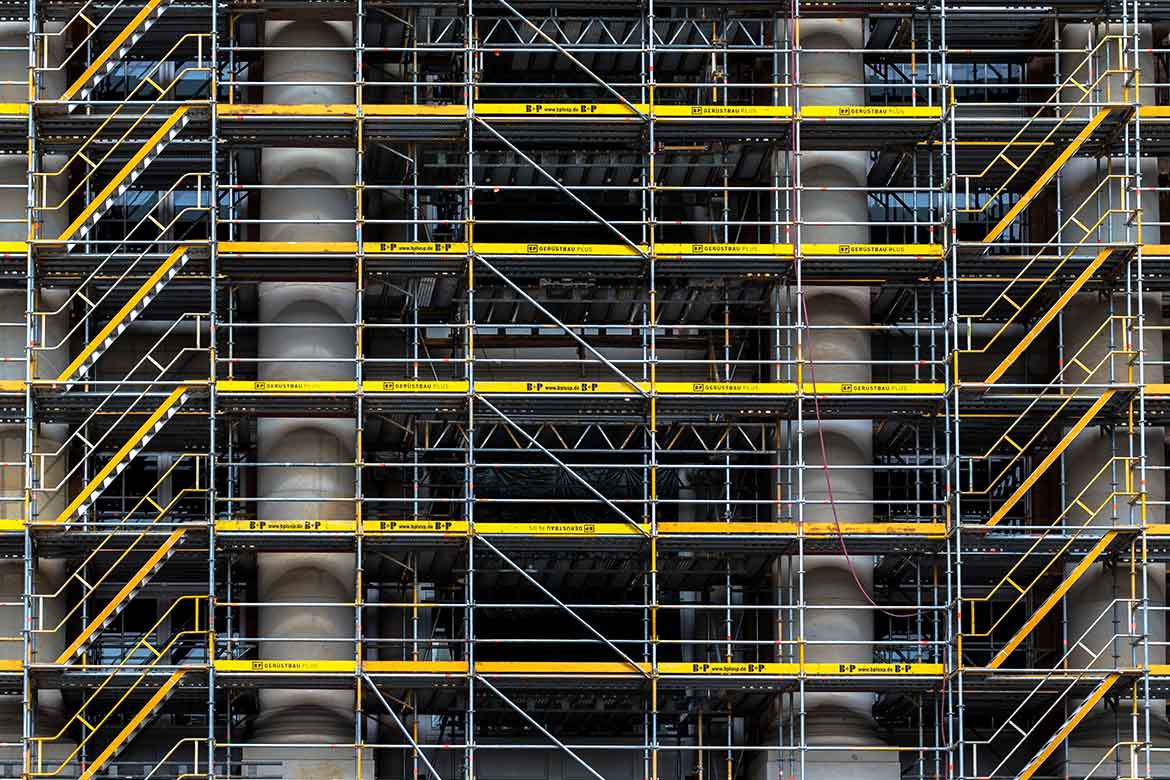

There's a hierarchy of control for working at height that must be followed. Think carefully about your access equipment. Scaffolds need to be correctly installed by a trained and skilled team and formally inspected every 7 days. A step ladder is fine for changing a light bulb, but not for plastering a ceiling.

Don't forget, with any outside work, the weather can play a huge part in increasing the risk, and work at height should not be carried out in windy, icy or very wet conditions.

You don't have to be high up for a fall to be serious. Even falls from low heights can be fatal.

Need Help? Download the work at height risk assessment template.

2. Falling/Moving Objects

Next on our list is falling and/or moving objects.

Construction sites are busy places and often involve a variety of trades working closely together to both demolish and build. Considering this fact, it is no surprise that falling and moving objects are a major hazard, as different people and teams work throughout the site to get the project completed.

Construction sites get busy; not many workplaces have to be as alert when it comes to watching out for moving materials, equipment and vehicles.

Contact with moving/flying/falling objects accounted for 21% of fatal injuries in the construction industry 2023/24 HSE accident statistics. And contact with moving vehicles caused a further 10% of fatalities. Struck by moving/flying/falling objects also caused 14% of non-fatal injuries in construction in 2023/24.

Carefully planning lifting operations, exclusion zones below overhead work, ensuring communication between the various trades on site and always wearing appropriate PPE on site will help to protect you from falling and moving objects.

And with machinery, deliveries and other vehicles all needing access close to work areas, construction traffic management is another important consideration to prevent fatal and serious accidents to your workforce.

Need Help? use the construction traffic management plan template.

3. Electricity

Electricity can kill, and leads to several deaths each year in the construction industry, and dozens of serious injuries (25 in 23/24). It's not just electricians at risk; accidental contact with hidden services is a hazard for all trades on site.

Before starting work, identify the location of electrical services, and make sure electrical work is only undertaken by a qualified and competent electrician.

When you are working near electrical wiring or equipment, the electrical supply should be turned off. Again, a competent person will need to carry out any work on electrical systems to ensure that the circuit is no longer live and it is safe for work to proceed.

⚠️ Always assume electricity is live unless it is proved otherwise.

Electrical tools used on site should only be 110V to reduce the risk, with regular inspections and any faulty equipment or leads taken out of use for replacement or repair.

And don't forget about overhead and underground services. Follow safe digging practices. Before excavating, make sure any electrical or other services are identified and marked on site, isolated or disconnected as required if there is a risk of contact. Overhead power cables should also be identified and precautions such as barriers, height restrictions of plant, isolation or re-routing taken as required.

Need Help? Download the pre-completed electrical risk assessment template.

4. Collapse

This is more of a risk than a hazard. Collapse and overturning were the cause of 11% of construction deaths in 2023/24.

The risk of a collapse is at its greatest during demolition works or when a building or structure is partially completed, such as incomplete access equipment, i.e. scaffolding. Structures can become unstable during modification, alteration and demolition.

Any building demolition work, no matter how small, should be carefully planned by a competent person, in a logical sequence, with any necessary temporary supports put in place to ensure that an unplanned collapse of the structure does not happen.

It's not just permanent structures that can collapse. Scaffold collapses are rare, but when they do happen, they are almost always fatal. Make sure that scaffolding is erected by a competent team, inspected every 7 days or after any event that may affect its stability, such as extreme weather.

Need Help? Download the pre-completed demolition method statement template.

5. Handling Loads

Regardless of what part of the construction process you are involved with, if you are building something or knocking it down, you need to move materials and equipment to get the job done.

While moving loads is unlikely to kill you, it does feature in the top 5 causes of specified (7%) and over 7-day (24%) injuries in 2023/24. Being injured while handling, lifting or carrying is often the largest cause of over 7-day injuries in construction, and this remains the case in the 23/24 accident statistics.

Musculoskeletal disorders, often caused by manual handling injuries, are also significantly higher in the construction industry (2%) compared to all industries (1.2%).

So, what can you do to reduce the risk?

First, eliminate manual handling where possible and use mechanical means instead, particularly when moving heavy and bulky loads. Reduce the strain by using team lifts when mechanical means are not practical. And finally, know your manual handling limits and practice safe lifting.

If something is beyond your capabilities to lift safely, get help with it. After all, pride comes before a fall... or should that be an injury in this instance?!

Need help handling? Download the ready-to-use manual handling risk assessment template.

This blog post was first written in 2013 and has since been updated with the latest accident statistics*.

*Construction statistics published by the Health and Safety Executive (HSE) and licensed under the Open Government Licence v1.0

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Need health and safety documents?

Search hundreds of health and safety documents ready to edit and download for your construction projects.

Find DocumentsRecent posts like this...

The 10 Rungs (And Rules) Of Ladder Safety

Used right, ladders are not particularly dangerous. But ladders are involved in over a quarter of all falls from height, causing serious and sometimes fatal injuries. Our 10 rules of ladder safety will help you use ladders correctly, to help prevent you from getting hurt.

Read Post

Securing Your Construction Site For Christmas Shutdown

Christmas is often the longest period your construction site will be closed, so site security is especially important. Because when you're away, things can go wrong. Shutting down your site and securing it from trespassers can help make sure that you don't get any nasty surprises.

Read Post

10 Winter Safety Tips For Construction Workers

Working outside in the winter can be a challenge for keeping warm, but winter work can also create safety hazards and increase the risk of accidents on site, due to poor weather conditions, reduced lighting, and hidden dangers. Here are 10 winter safety tips for construction workers.

Read Post