11th August, 2021

Manual Handling And The Maximum Weight You Can Lift

How much weight is safe to lift and carry at work? Lifting, moving and carrying are part of most jobs. From time to time, or all the time. We need to know if a load is safe to lift - or not. But what are the legal limits and guidelines surrounding manual handling?

You lift and carry things all the time. Manual handling happens in nearly every workplace in one form or another. Whether you are moving boxes in an office, carrying bricks on a construction site, or even lifting and moving people in health professions.

Lifting, moving and carrying are part of most jobs, from time to time, or all the time. Because it happens so often, most of the time, you probably don't give it much thought. When things are part of everyday life, people often assume they are safe. But is it? Let's take a look at the HSE statistics to find out.

According to HSE statistics, 480,000 workers suffered from work-related musculoskeletal disorders in 2019/20. That's a lot of suffering! And in the same year, over 8.9 million working days were lost due to work-related musculoskeletal disorders.

To put these numbers into context, musculoskeletal disorders accounted for 30% of all work-related ill health and 27% of working days lost by ill health. So a large proportion of ill health at work is from musculoskeletal disorders. And manual handling is the leading cause of musculoskeletal disorders, including back disorders and upper limb disorders.

Manual handling, awkward or tiring positions and keyboard work or repetitive action are estimated to be the main causes of work-related musculoskeletal disorders based on 2009/10-2011/12 LFS data.

These types of disorders are often long term ill-health problems. As in, they develop over time through poor manual handling. But manual handling doesn't just cause ill health. It's also responsible for injuries at work. In fact, lifting and carrying accounted for 19% of all non-fatal injuries in 2019/20. That's over 130,000 people injured at work during manual handling.

With manual handling being the leading cause of musculoskeletal disorders at work, and responsible for a significant number of injuries, it’s important to know how much you can safely lift. So how much weight is safe to lift and carry at work? What are the maximum weights you can handle?

What are maximum manual handling weights?

Ok, so back to the question, how much is too much when it comes to manual handling? Well, this might surprise you, but there is no 'safe lifting weight' or 'maximum lifting weight' set by the regulations.

Often, people think there is a limit, for example, 25kg per person, but that's not the case. The Manual Handling Operations Regulations (which are the law around manual handling) set no specific weight limit requirements. Maybe we should add that to our health and safety myths!

The law does not identify a maximum weight limit. It places duties on employers to manage or control risk; measures to take to meet this duty will vary depending on the circumstances of the task.

And if you think about it, it is easy to see why setting a weight limit would not be practical. People are all different and have different capabilities. The world’s strongest man could safely lift a weight above that of the average male. And people have different fitness levels, health requirements, and conditions.

People’s requirements and capabilities can also change over time. What someone was able to lift safely several years ago might have changed. Maybe they got ill and became weaker. Or perhaps they went on a health kick and got fitter. If nothing else, they definitely got older.

As you can see, there are many reasons why setting one safe weight for everyone to lift would not be suitable. And would not be safe.

So how much is safe to lift and carry?

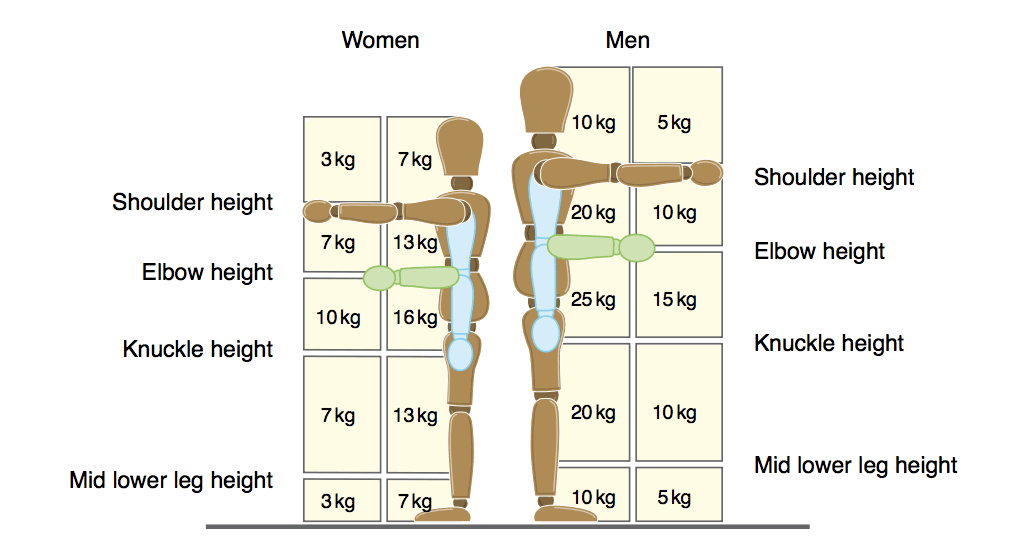

Instead of maximum or safe lifting weights for manual handling, there are guidance weights, published by the HSE (which is where the 25kg for men often comes from).

But these guidance weights shouldn't be confused with a weight limit. Or a safe lifting weight. Think of them as guidance, they give basic guideline amounts for lifting, carrying and lowering. It tells you when a more detailed risk assessment should be carried out. If you are outside of these guideline amounts, you need to be carrying out a more detailed manual handling risk assessment.

Even if you are inside the guidelines, you need to put the I in LITE and think about the individual.

Learn how to apply LITE to your manual handling assessments with our blog post Manual Handling? Think LITE!

The elderly members of your workforce may not be comfortable lifting what they used to. And pregnant workers, and workers with medical conditions or injuries most certainly shouldn’t be lifting what they used to.

You should also take into account the task. For example, you may be comfortable lifting a weight of 15kg twice a day as part of your job, maybe even once an hour. But what if you were required to lift the weight repeatedly throughout the day, every minute? Would that be practical? Would it be safe?

This highlights the need to assess manual handling operations individually, and helps to explain why the regulations shy away from setting a 'safe lifting weight' or a 'maximum manual handling weight'.

How can you assess safe manual handling weights?

So if the regulations don't tell you what the maximum weights are, how do you know? Well, it all comes down to a process known as risk assessment.

While the regulations don't tell you what weight you can lift, they do tell you that you need to assess manual handling operations, reduce the risk of injury and provide information on the general weights involved.

- so far as is reasonably practicable, avoid the need for his employees to undertake any manual handling operations at work which involve a risk of their being injured; or

- where it is not reasonably practicable to avoid the need for his employees to undertake any manual handling operations at work which involve a risk of their being injured—

- make a suitable and sufficient assessment of all such manual handling operations to be undertaken by them[...]

Different conditions and different people mean each manual handling operation is unique. And several different aspects will have an impact on the maximum or safe weight you could handle.

It's your responsibility as an employer to reduce risk and keep your workers safe. So rather than thinking about the maximum weight, you should consider how to reduce risk. Or to put it another way, how can you reduce manual handling to avoid related ill-health and injuries.

Your assessment should consider all of the following:

- the task

- the load

- the working environment

- individual capabilities

- other factors, for example, the use of protective clothing

Don’t forget, all of the above categories are important and one may influence the other. As we discussed in the example above, individual capabilities may change based on the task and the load. The working environment can also have a big impact on the safety of manual handling operations, affecting posture and lifting positions.

When assessing the safety of manual handling operations remember to follow the hierarchy of controls set out in the regulations which include:

- Avoid manual handling as far as reasonably practicable

- Make a suitable assessment of any hazardous manual handling operations that can’t be avoided

- Reduce the risk of injury as far as reasonably practicable, through mechanical assistance or changing the task, load or working environment to improve safety

Need help creating your manual handling risk assessment? Download our manual handling risk assessment template to create a professional assessment and ensure you have covered all areas.

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Can you handle this?

Take our manual handling elearning course and get your certificate today.

Course InfoRecent posts like this...

TILE Manual Handling Considerations (And What Is TILE?)

When you are manual handling, you need to know about TILE. But what is TILE? TILE is the four key areas you need to consider when lifting or carrying - Task, Individual, Load, and Environment.

Read Post

Manual Handling? Think LITE!

Manual handling is the leading cause of musculoskeletal disorders at work. To avoid pulled muscles and painful joints, it's important to know how much you can safely lift, and use good handling techniques. In this blog post, we learn how to think LITE.

Read Post

13 Types Of Manual Handling Injuries And The Hazards That Cause Them

It might surprise you that manual handling is responsible for over 30% of workplace injuries. For something so simple, why so many accidents? Well, it's likely to be because we don't expect anything to go wrong - we lift things all the time.

Read Post